- mold base, die set or metal processing Kawashima Kinzoku Co., Ltd.

- Strengths of Kawashima Kinzoku

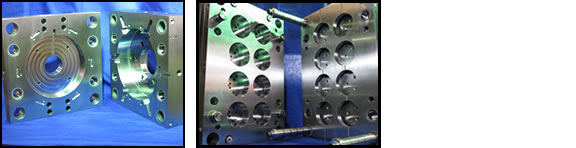

We have considerable experiences of manufacturing mold bases for various applications, including optical and medical equipment, in-vehicle devices, stationeries and two-color molding products. We have accumulated abundant technologies through a long-term technological collaboration with camera manufacturers, and today we are covering a wide array of fields by applying those technologies.

- We can keep the hole position accuracy up to approx. 0.01 mm between the plates.

- For the grinding accuracy, we can finish the plates up to the micron level by finding out minute warpage and distortion.

- The time we need for manufacturing a mold base is only two weeks at longest for the whole process including inspection.

- We can handle 3D data (e.g. STEP, IGES or PARASOLID).

Example of a manufacturing schedule

(Description)

Retainer plate size: 300 x 300, pin gate type, slide: four-way sliding, support plate, EP hole

- Material taking (coming in the 2nd or 3rd day): 1 or 2 days

- Water hole processing: 3rd day

- Rough processing: 3rd to 4th day

- Finishing processing: 5th to 7th day

- Side processing: 8th day

- Inspection: 9th day

- Packing & shipment: 10th day

If you specify your target delivery sufficiently in advance, we can deliver the product in approx. one week by arranging our process.

1. Temperature control by thermostatic chamber

We use the thermostatically-controlled factory without windows for finishing of mold bases, and the temperature in the factory is strictly controlled to stay at 23±1℃. All the outer walls of the factory are made of insulation panels, which prevent temperature changes caused by the weather, typically by the external air. This thermostatic control can minimize the expansion, shrinkage and alternation of plates to enable us to keep the high quality and high precision of mold bases.

2. Environment for machinery

The insulation panels of the outer walls are also electromagnetically shielded to shut outexternal noises including electric and magnetic waves, so that malfunction of the machinery can be avoided. We have a dedicated cubicle system for the factory to eliminate instability of power supply, so machines can always work in a stable manner. The foundation of the machining center is divided and reinforced for each machine.

3. Testing equipment

We use ceramic block gages by Mitutoyo for testing. They do not thermally expand to avoid variance of measurements. The measuring devices for Quality Control Division are used exclusively by QC Division without being shared by other divisions. They are stored separately at the special place for them.

We are a group of young people with the average age being 32 years old (male 31 and female 33).

To meet the needs of quick response and short delivery, we have developed robust logistical support to try to answer the customers' inquiries as soon as possible.

Even when our sales engineers are not available, we have always ten female support staff to respond to the customers' inquiries and requests for estimate.We are proud that every staff can comprehend technical drawings.

Sales & Marketing Division

All the staff in this division share the information through daily assemblies held in the morning and the evening; in the assemblies present orders and schedules are carefully checked.

In addition, each person makes a plan including the strategy for the next day and it is constantly reviewed by the supervisor.

Manufacturing Division

The average age of operators is 26 years old. There are many young people working in this division and female operators also play an active part. We have a policy that every staff should be aware of the customers' viewpoint and so let an operator visit a customer with a sales engineer whenever possible. The operators have a morning assembly every day to discuss the daily process, and in addition to that they have a general meeting at the beginning of a month, so that the customers' newly presented demands can be achieved in the next job. This way, we can grow up in harmony with the development of mold bases.